• Medical

• Automobile seat/headrest

• Sound insulation products

• Electronic

• Suitable for blister filling foam processing products

• Outdoor sports products

• Shock absorption products

• Foam process bicycle cushion

Descriptions

Specifications:

Thickness: 0.05-2mm (can be customized)

Width: 10-1500mm (can be customized)

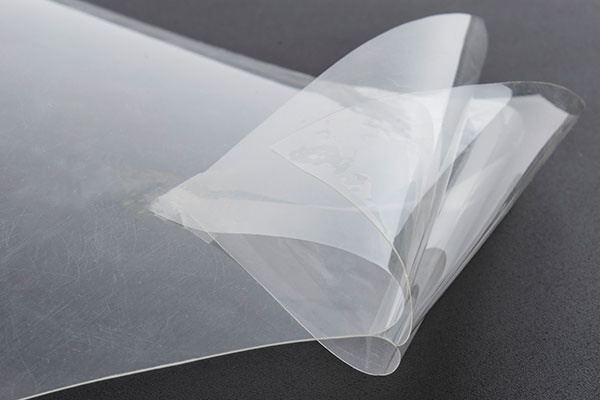

Color: transparent, foggy (any colors can be customized)

Advantages

Polyester TPU film has better heat resistance and chemical solvent resistance, good air tightness AND easy to process, widely used to replace PVC film for various purposes.

Processing is simple and convenient: TPU film is easier to process than PVC film by means of high frequency, hot pressing and other processing methods, it is better than PVC film after appropriate adjustment of hot pressing time, temperature and pressure.

Acid and alkali oil resistance: polyester TPU film is a strong polar polymer material, and non-polar mineral oil affinity is very small, almost no erosion in fuel oil and machinery oil.

Aging and oxidation resistance: polyester film has better physical properties, such as tear strength, tensile strength, elongation, etc.Therefore, its aging resistance and oxidation resistance is also good.

Better air tightness: suitable for air bag cushion, inflatable products and blowing toys.

It can be widely used to replace various uses of PVC.

Applications

Home textile, raincoat, apron,bags, shower curtain, table cloth, label

Automobile, seat, headrest

Outdoor sports products, tent, balloon, water bladder, jacket

Electron industry, phone case, keyboard, sound, viewing screen

Medical, infusion bag, ice pack, air mattress

Physical Performance

| TEST ITEM | TEST METHOD | UNIT | TEST VALUE |

| Hardness | ISO 686 | shoreA | 90 |

| Specific Gravity | ISO 2781 | g/cm³ | 1.2±0.02 |

|

Thickness Color |

Thickness Gauge Visual Inspection |

mm / |

0.05-2.0 Customized |

| Tensile Strength | ISO 527-3/5/500 | MPa |

CD: 40.52 MD: 37.4 |

| Tensile Strength @ 50% Elongation | ISO 527-3/5/500 | MPa |

CD: 5.58 MD: 5.70 |

| Tensile Strength @ Elongation | ISO 527-3/5/500 | MPa |

CD: 6.74 MD: 6.51 |

| Tensile Strength @ 300% Elongation | ISO 527-3/5/500 | MPa |

CD: 14.06 MD: 11.62 |

| Elongation at Break | ISO 527-3/5/500 | % |

CD: 691 MD: 636 |

| Tear Strength | ASTM D1004 | kg/cm |

CD: 95 MD: 98 |

| Abrasion Resistance | ISO 4649 | mm³ | 37 |

| Vicat Softening Point | ISO 306 | ℃ | 90℃ |

| Melting Point | Kofler | ℃ | 165-170 |

| Brittle Point | DSC | ℃ | -30℃ |

| UV Light Discoloration | ASTM D1148 | Grade | 4-4.5 |